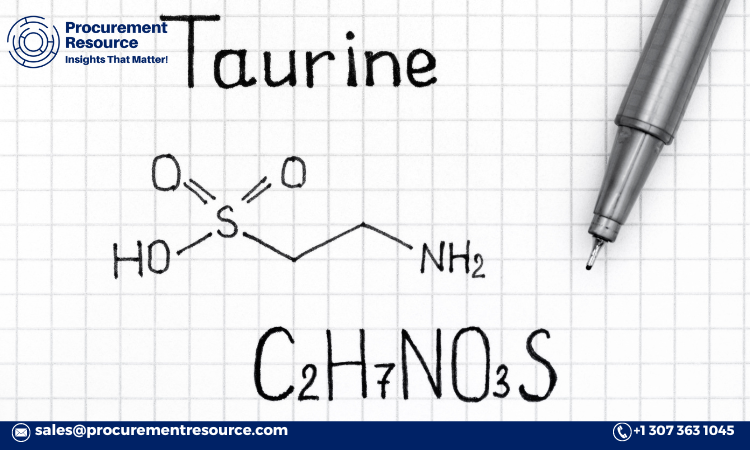

Taurine is a vital amino acid that plays a crucial role in numerous physiological functions, including bile salt formation, eye health, heart function, and development and function of skeletal muscle, the central nervous system, and the cardiovascular system. It is found abundantly in animal tissues and is a common ingredient in energy drinks, supplements, and pet foods. The demand for taurine has surged due to its extensive use in the health and wellness industry, which has, in turn, led to a significant interest in understanding the production costs associated with taurine. This blog delves into the taurine production process, providing a detailed manufacturing report and an analysis of the raw material costs involved.

Manufacturing Report and Process

Chemical Synthesis

Taurine production primarily involves chemical synthesis, which is the most prevalent method used in industrial settings. The chemical synthesis of taurine typically involves two key steps:

Request For Sample: https://www.procurementresource.com/production-cost-report-store/taurine/request-sample

-

Ethylene Oxide Route: This method involves the reaction of ethylene oxide with sodium bisulfite, resulting in the formation of isethionic acid. The isethionic acid is then ammonolyzed to produce taurine. This process is highly efficient and is widely adopted due to its cost-effectiveness and scalability.

-

Aziridine Route: Another method involves the reaction of aziridine with sulfurous acid, which directly yields taurine. Although this method is less common, it is noted for its simplicity and direct approach.

Fermentation Process

An alternative to chemical synthesis is the fermentation process, which involves the use of microorganisms to produce taurine. This method is considered more environmentally friendly and sustainable. The fermentation process includes:

-

Microbial Fermentation: Specific strains of bacteria or yeast are genetically engineered to produce taurine. The microorganisms are cultivated in a controlled environment where they convert substrates like glucose into taurine through a series of metabolic reactions.

-

Extraction and Purification: The taurine produced by the microorganisms is then extracted and purified using various techniques such as filtration, centrifugation, and crystallization. The final product is then dried and packaged for commercial use.

Production Workflow

Regardless of the method used, the taurine production workflow generally follows these steps:

-

Raw Material Preparation: The necessary raw materials, including ethylene oxide, sodium bisulfite, or microbial cultures, are prepared and pre-treated as required.

-

Reaction Phase: The primary chemical reactions or fermentation processes are carried out in reactors or bioreactors under controlled conditions of temperature, pH, and pressure to optimize yield.

-

Separation and Purification: The crude taurine mixture undergoes several purification steps to remove impurities and by-products. Techniques such as distillation, filtration, and crystallization are commonly employed.

-

Drying and Packaging: The purified taurine is then dried to remove any residual moisture, followed by packaging into appropriate containers for storage and distribution.

Raw Material Costs

Understanding the raw material costs is crucial for determining the overall production cost of taurine. The primary raw materials involved in taurine production include ethylene oxide, sodium bisulfite, and sulfurous acid for chemical synthesis, or glucose and microbial cultures for the fermentation process. The cost of these raw materials can significantly impact the production cost, and it is essential to monitor their market prices closely.

Chemical Synthesis Raw Material Costs

-

Ethylene Oxide: This is a key reactant in the synthesis of isethionic acid, a precursor to taurine. The cost of ethylene oxide is influenced by the petrochemical industry, as it is derived from ethylene, a by-product of petroleum refining. Fluctuations in crude oil prices can directly impact the cost of ethylene oxide.

-

Sodium Bisulfite: Used in the ethylene oxide route, sodium bisulfite is a widely available chemical with relatively stable pricing. However, its cost can be affected by supply chain dynamics and regulatory changes related to its production and use.

-

Sulfurous Acid: In the aziridine route, sulfurous acid is utilized, and its cost is dependent on the availability of sulfur dioxide, a by-product of various industrial processes. Market demand for sulfur dioxide in other applications can influence the price of sulfurous acid.

Fermentation Process Raw Material Costs

-

Glucose: A primary substrate for microbial fermentation, glucose is typically derived from corn or other starch-rich sources. The cost of glucose is influenced by agricultural factors, including crop yields, weather conditions, and market demand for corn-based products.

-

Microbial Cultures: The cost of genetically engineered microbial strains used in fermentation can vary based on the complexity of the genetic modifications and the scale of production. Maintaining a stable and high-yielding microbial culture is essential for cost-effective production.

-

Nutrient Media: The microorganisms require specific nutrient media for optimal growth and taurine production. The cost of these media components, such as nitrogen sources, vitamins, and minerals, must be factored into the overall production cost.

Cost Analysis and Market Trends

The cost of taurine production is subject to various factors, including raw material prices, energy costs, labor, and regulatory compliance. Additionally, advancements in production technologies and economies of scale can help reduce costs over time. Monitoring market trends and developments in the chemical and biotechnology industries is crucial for staying competitive.

-

Energy Costs: Energy consumption is a significant cost component in taurine production, particularly in the chemical synthesis route. Fluctuations in energy prices can impact the overall production cost.

-

Labor Costs: Skilled labor is required to operate and maintain production facilities. Labor costs can vary by region and influence the competitiveness of taurine producers.

-

Regulatory Compliance: Adhering to environmental and safety regulations can add to the production cost. However, regulatory compliance is essential for sustainable and responsible production practices.

Conclusion

The production of taurine involves complex processes that can be carried out through chemical synthesis or microbial fermentation. Understanding the intricacies of the manufacturing process and the associated raw material costs is essential for optimizing production and managing expenses. As the demand for taurine continues to grow, advancements in production technologies and cost-efficient methods will play a pivotal role in meeting market needs while maintaining profitability.