In the dynamic landscape of fuel additives, isooctane stands out as a crucial component known for its high octane rating and efficiency in enhancing gasoline performance. Understanding the production cost dynamics of isooctane is essential for stakeholders aiming to navigate the complexities of the energy sector effectively.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/isooctane/request-sample

Procurement Resource Assessment of Isooctane Production Process:

Procurement Resource offers a detailed assessment of the isooctane production process, providing invaluable insights into the various methodologies and technologies employed. This assessment ensures that businesses can make informed decisions based on comprehensive data and analysis.

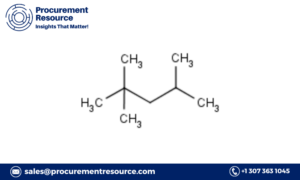

Product Definition:

Isooctane, also known as 2,2,4-trimethylpentane, is a branched-chain hydrocarbon primarily used as a blending component in gasoline to improve its octane rating. It is synthesized through specific chemical processes designed to achieve optimal purity and performance-enhancing properties.

Market Drivers:

The demand for isooctane is predominantly driven by the automotive industry’s increasing focus on higher octane fuels, which enable more efficient combustion and reduced emissions. Moreover, regulatory trends favoring cleaner fuels further underscore the importance of isooctane in achieving environmental compliance.

Raw Materials Requirements:

The production of isooctane requires precise raw material inputs, including hydrocarbons such as isobutylene and isobutane, which are crucial for achieving the desired chemical composition and purity levels. Understanding these raw material requirements is pivotal for assessing cost structures and supply chain efficiencies.

Costs and Key Process Information:

Key cost components in the production of isooctane include raw material procurement, energy consumption, labor costs, and capital investments in specialized equipment. Detailed analysis of these factors provides a comprehensive view of production economics and potential cost-saving opportunities.

Exhaustive and Personalized Report:

Stakeholders seeking an exhaustive and personalized report on isooctane production costs will benefit significantly from Procurement Resource’s comprehensive insights. This report not only covers cost analysis but also delves into market trends, competitive landscape, and strategic recommendations tailored to enhance business decision-making.

Conclusion:

In conclusion, the isooctane production cost analysis report from Procurement Resource offers unparalleled insights into the intricate dynamics shaping the fuel additive market. By leveraging this comprehensive analysis, businesses can gain a competitive edge and navigate the evolving energy landscape with confidence.

Contact Us:

Company Name: Procurement Resource

Contact Person: Christeen Johnson

Email: [email protected]

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA